FDM is the most common and economical 3D Printing technology today. The inventor of FDM technology is Scott Crump, who is also the co-founder of the famous 3D Printing technology company Stratasys. Fused deposition modeling is also called fused filament deposition modeling (FDM), and its raw materials are various thermoplastic plastic filaments.

During the molding process, the filamentous hot-melt material is heated and melted, extruded through a nozzle with a fine nozzle, and deposited on the substrate or the previous layer of solidified material. When the temperature is lower than the solidification temperature, the deposited filament material starts to solidify, and finally forms a three-dimensional object through the accumulation of layers of materials.

FDM is easy to manufacture and low in cost. However, due to the simple structure of the output material, it is difficult to accurately control the output shape and the forming effect. The finished product of the desktop FDM printer has low precision and the effect is unstable.

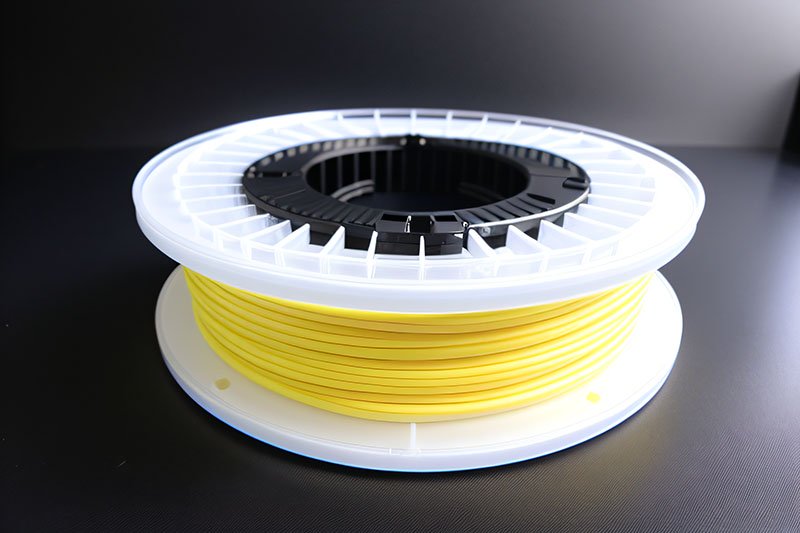

Commonly used printing consumables for FDM are PLA (polylactic acid) and ABS, among which PLA is widely used due to its good environmental performance.

Yoddon offers 3D Printing services for your prototyping and production needs. If any interest, please feel free to Contact us.