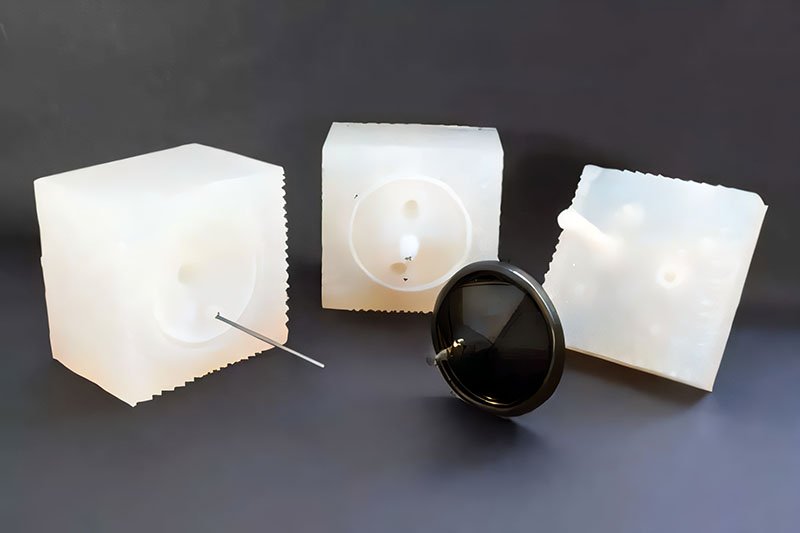

Vacuum Casting is a method used to mold thermosetting polyurethane for prototypes, one-offs and low volumes, it can replicate almost all the properties of injection molding. Flexible silicone molds are produced directly from the master. Vacuum Casting is then used to reproduce the product properties.

Related Processes : Injection molding and Reaction Injection Molding

Applications for Vacuum Casting are widespread and used in the automotive (inlet manifold, water tanks, air filter housings, radiator parts, lamp housings, clips), consumer electronic, consumer product, toy and sport equipment industries. As well as prototyping, it is used when low volumes rule out expensive tooling for injection molding. Compared to RIM process, Vacuum Casting is suitable for smaller and more complex products.

Reaction Injection moulding is also used for prototyping, one-offs and low volume production. But due to the nature of the process, it is best suited to parts with simpler geometries and smoother features. Such as, car bumper and dashboards. It is due to the speed that the polyurethane cures in the RIM process.

Costs

Low tooling costs,moderate unit costs.

Quality

Very high surface finish and reproduction of detail.

Vacuum Casting is cost-effective and faster for producing duplicate prototypes or small batch production. Yoddon has the best Vacuum Casting services for you.