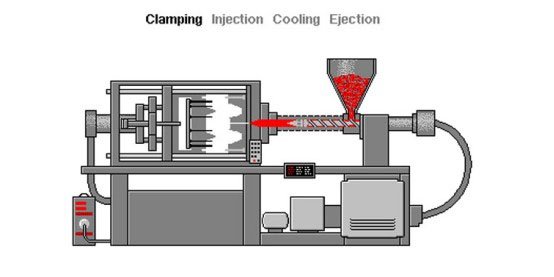

Plastic injection molding is a popular and economical industrial process for manufacturing a wide range of plastic products. It is a process where plastic is heated and passed into a mold for large volume production of various items.

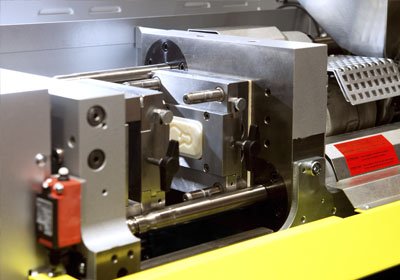

In the plastic injection molding process, plastic materials is forced into a mold cavity under pressure that contains the cavity corresponding to the part design. Pelletized resins are fed into the injection molding machine, as well as any colorants required.After the cavity fills, the machine continues to pack melted plastic material that solidifies after it cools down. Once cooled, the solid molded part can be removed from the cavity.

AdvantagesPlastic injection molding machines have several critical advantages that gave them their popularity. They can produce items in large quantities in a relatively short period of time.

Yoddon is specialized in various custom plastic molds manufacturing for automotive, home appliances, electronics, as well as general industrial OEM applications.