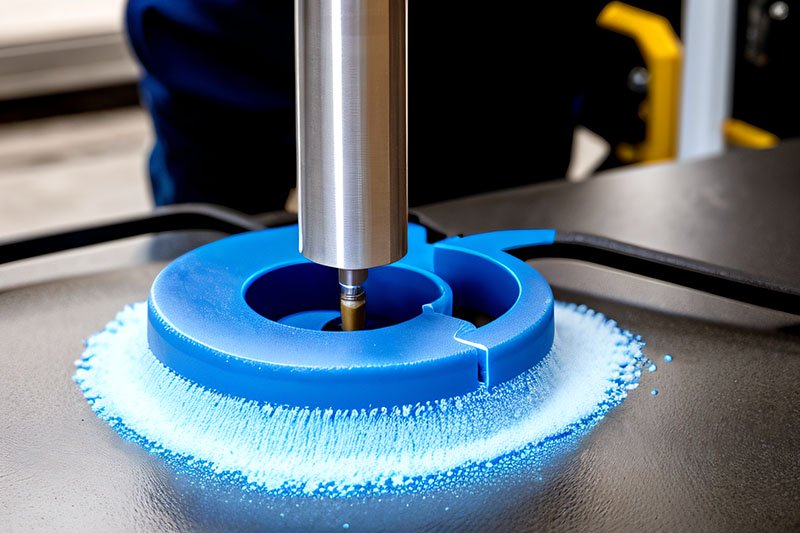

In the CNC process, in order to improve the processing efficiency, improve the precision of machine parts, reduce the surface roughness of machine parts, prolong the service life of the tool, and achieve the best economic effect, it is necessary to reduce the friction between the tool and machine parts, and between the tool and the chip, and bring away the heat generated by the deformation of the material in the cutting zone. Therefore, cutting fluid is essential in the CNC process.

At present, there are many kinds of cutting fluids with different functions, but they are mainly divided into two categories: oil-based cutting fluids and water-based cutting fluids.

Let us learn about the role of cutting fluid:

The cooling effect is to rely on the convective heat transfer and vaporization of the cutting fluid to take away the cutting heat from the solids (tools, machine parts and chips), reduce the temperature in the cutting zone, reduce the deformation of the machine parts, and maintain the hardness and size of the tool.

In the CNC process, friction occurs between the tool and the chip, the tool and the surface of machine parts, and the cutting fluid is a lubricant to reduce this friction.

During the CNC process, chips, iron powder, grinding chips, oil stains, etc. are easy to adhere to the surface of the machine parts, the tool, and the grinding wheel, which affects the cutting effect, and at the same time makes the machine parts and machine tool dirty and difficult to clean, so the cutting fluid must have good cleaning effect.

During the CNC process, if the machine part is in contact with the corrosive medium produced by the decomposition or oxidative deterioration of water and cutting fluid, such as sulfur, sulfur dioxide, chloride ions, acid, hydrogen sulfide, alkali, etc., it will be corroded. After the machine parts are processed or stored during the process, if the cutting fluid does not have a certain anti-rust ability, the machine parts will be eroded by moisture in the air and corrosive media to cause chemical corrosion and electrochemical corrosion. Therefore, the cutting fluid generally has a certain anti-rust ability.

If you are looking for a reliable, quick-turn supplier of machined plastic and metal parts ? There is no doubt that Yoddon is the best choice. Contact us and start to get a quote.