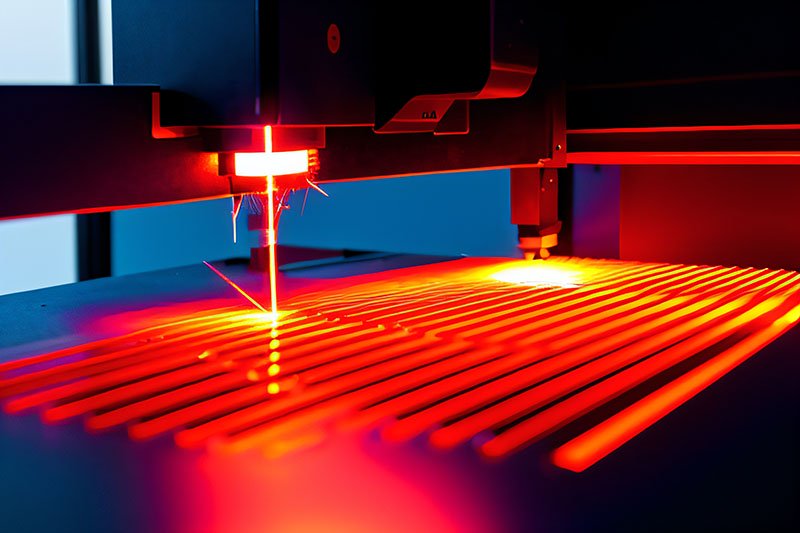

This is a high precision CNC process that can be used to cut, etch, engrave and mark a variety of sheet materials including metal, plastic, wood, textiles, glass, ceramic and leather.

Applications are diverse and include model making, furniture, consumer electronics, fashion, signs and trophies, point of sale, film and television sets, and exhibition pieces.

The choice of material will determine the quality of the cut. Certain materials, like thermoplastics, have very high surface finish when cut in this way. Laser processes produce perpendicular, smooth, clean and cuts with a narrow kerf in most materials.

These processes can be used to cut a multitude of materials including timber, veneers, paper and card, flexible magnets. Compatible plastics include PP, PC, PMMA, PA, POM. Of the metals, steels cut better than aluminium and copper alloys, for example, because they are not as reflective to light and thermal energy.

There are no tooling costs for this process.Date is transmitted directly from a CAD file to the laser cutting machine. Cycle time is rapid but dependent on material thickness. Thicker materials take considerable longer to cut.

Contact us to get started with a free project review and quote to learn more about our laser cutting services.