Spray coating is the application of liquid borne materials onto a surface. It is a fast and efficient means of applying adhesive,primer,paint. Spray painting is used in a vast range of applications including prototyping, low volume and mass production.

Automotive and transportation

Consumer electronics and appliances

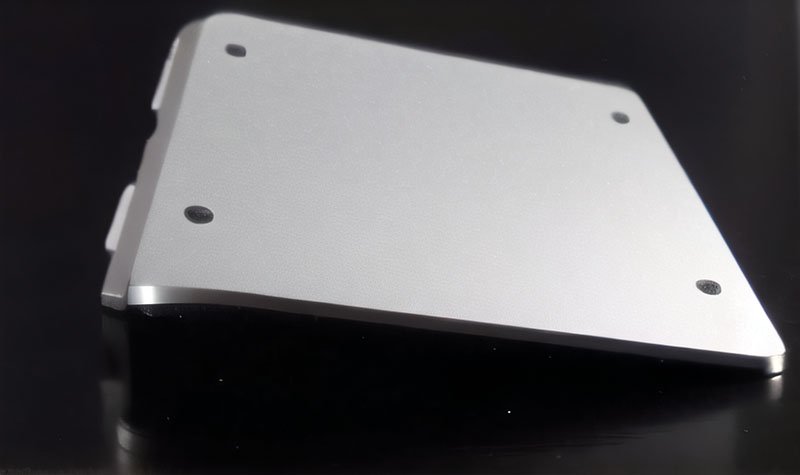

This is a generic term used to describe the process of surface removal by fine particles of sand, metal, plastic or other abrasive materials, which are blown at high pressure against the surface of the part and produce a finely textured finish.

PC part, Metal parts

Power Coating is primarily used to protect work from corrosion and damage. It is a dry finishing process that is used to coat a range of metalwork by either spray or a fluidized bed. The powder adheres to the part electrostatically and is cured in an oven to produce a glossy protective coating.

Currently,aluminum and steel are the most widely powder coated materials. Powder coating is suitable for both functional and decorative applications. Such as automotive, indoor and outdoor furniture,domestic and office products.

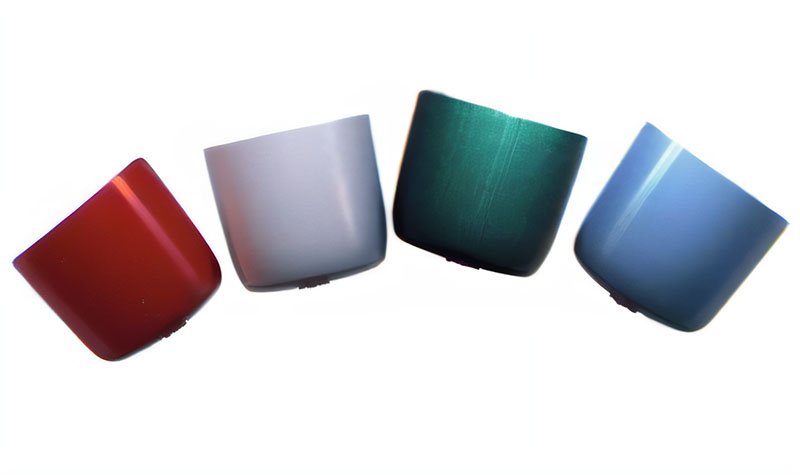

Anodizing is used to protect and enhance metal for both indoor and outdoor use. Indeed, most aluminium in the automotive,consumer electronics industries is treated this way. The surface of aluminum,magnesium and titanium can be anodized to form a protective oxide layer. It is naturally light grey, but can be electrolytically coloured or dyed, with a range of vivid colors including green, black and so on. Anodizing has 3 main stages: cleaning and etching, anodizing and sealing.

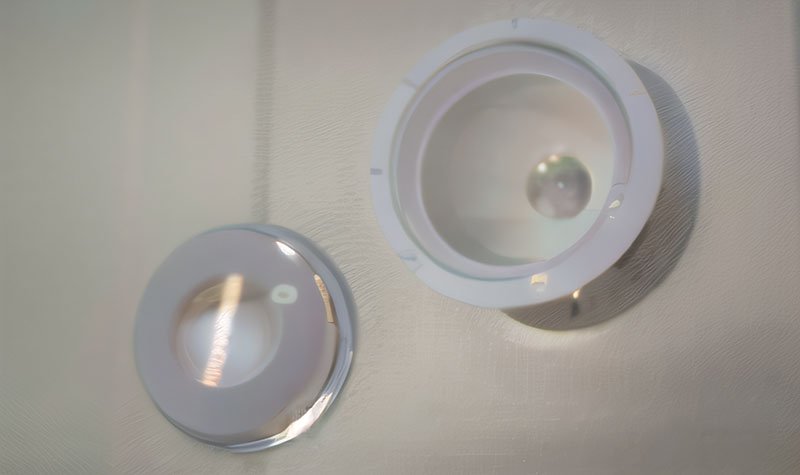

This is an electrolytic process used to apply a thin film of metal to another metal surface. A strong metallurgical bond is formed between the base material and coating. Electroplating produces a functional and durable finish.

Examples of electroplated plastic include automotive parts(gear sticks, door furniture and buttons), bathroom fittings, cosmetic packaging and trims on mobile phones, cameras.

Yoddon has years of experience in different surface treatment. The options listed here are not comprehensive, and there are additional ones available. Our team is ready to listen to your needs.