Sheet metal manufacturing is a common metal forming process used to manufacture various metal components, such as mechanical frames, doors and windows, pipelines, etc.

Design: Designers need to use computer-aided design software to design a three-dimensional model of the product based on its functional and appearance requirements.

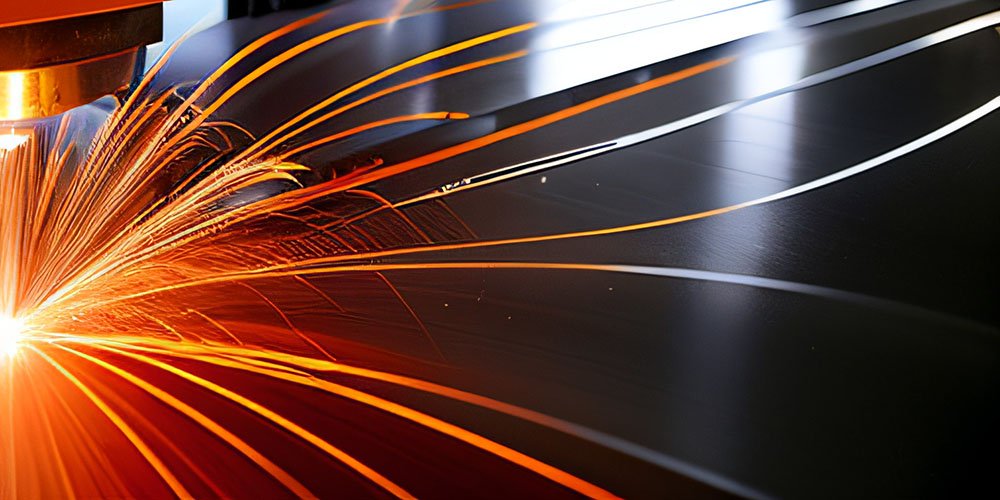

Making molds: Use stamping, bending, and other mold manufacturing processes to punch or bend the desired shape onto a metal plate.

Forming: Place the metal plate into a heat treatment furnace, remove excess and fix the shape.

Treatment and finishing: After forming, the metal plate needs to be treated and finished to remove burrs and improve surface smoothness.

Assembly: Assemble processed and precision processed metal plates together to form the final product.

Sheet metal manufacturing is very useful in manufacturing metal parts. It can provide high-precision and highly accurate products, which are crucial for manufacturing precision parts required by the aviation and defense industries. In addition, sheet metal manufacturing is also cost-effective and can produce high-quality products in a short period of time, thereby reducing production costs.

High precision and high accuracy: It can manufacture very precise parts with high dimensional stability and interchangeability.

Cost effectiveness: A large number of parts can be produced in a short period of time, thereby reducing production costs.

Manufacturability: It can be combined with other manufacturing processes to create complex parts.

The application fields of sheet metal manufacturing are very wide, including aerospace industry, automobile industry, construction industry, medical equipment, military equipment, etc.

Aviation and space industry: it is an important method for manufacturing high-precision and highly accurate parts required by aviation and national defense industries.

Automotive Industry: Manufacturing of automotive body structures and other components, such as doors, seats, instrument panels, etc.

Construction industry: manufacturing beams and columns of buildings, as well as other structural components.

Medical equipment: manufacturing medical equipment shells and other parts, such as brackets, scalpel handles, etc.

Military equipment: Manufacturing components for weapon systems and other military equipment.

Design: Designers need to use computer-aided design software to design a three-dimensional model of the product based on its functional and appearance requirements.

Making molds: Use stamping, bending, and other mold manufacturing processes to punch or bend the desired shape onto a metal plate.

Forming: Place the metal plate into a heat treatment furnace, remove excess and fix the shape.

Treatment and finishing: After forming, the metal plate needs to be treated and finished to remove burrs and improve surface smoothness.

Assembly: Assemble processed and precision processed metal plates together to form the final product.

With the arrival of Industry 4.0, sheet metal manufacturing will become more intelligent, automated, and efficient, while also improving production efficiency and product quality. In addition, with the development of 3D Printing technology, sheet metal manufacturing will also be combined with 3D Printing technology to produce more complex and high-precision products.

sheet metal manufacturing is a common metal forming process used to manufacture various metal components, such as mechanical frames, doors and windows, pipelines, etc. Sheet metal manufacturing has the advantages of high precision, high accuracy, cost-effectiveness and manufacturability. It is widely used to manufacture various types of metal parts, including aerospace industry, automobile industry, construction industry, medical equipment, military equipment, etc. With the arrival of Industry 4.0, sheet metal manufacturing will become more intelligent and automated, and it will also be combined with 3D Printing technology to manufacture more complex and high-precision products.