Mould is a fundamental technological device for industrial production. Industrially produced goods are formed in moulds which are designed and built specially for them. The mould is the core part of manufacturing process because its cavity gives its shape. There are many kinds of mould, such as casting & forging dies, ceramic moulds, die-casting moulds, drawing dies, injection moulds, glass moulds,magnetic moulds, metal extruding moulds, plastic and rubber moulds, plastic extruding moulds, powder metallurgical moulds, compressing moulds, etc.

The following is the introducton of some of themoulding process and the corresponding moulds used.

Compressionmoulding is the least complex of the moulding processes and is ideal for large parts or low-quantity production. For low-quantity requirements it is more economical to build a compression mould than an injection mould.Compression moulds are often used for proto-typing, where samples are needed for testing fit and forming into assemblies. This allows for further design modification before building an injectionmould for high-quantity production. Compression moulding is best suited for designs where tight tolerances are not required.

A compression mould is simply two plates with cavities cut into either one or both plates. For example, some mould does not require heater elements or temperature controllers. The moulding temperature can be fully controlled by the pressure it is running in.

Due to the simplicity of the mould, it is the most economical mould to buy. And the economical mould/tool cost keeps small quantity running affordable.

Injection moulding is the most complex of the moulding processes. Due to the more complex design of the injection mould, it is more expensive to purchase than a cast or compression mould. Although tooling costs can be high, cycle time is much faster than other processes and the part cost can be low, particularly when the process is automated. Injection moulding is well suited for moulding delicately shaped parts because high pressure (as much as 29000 psi) is maintained on the material to push it into every corner of the mould cavity.

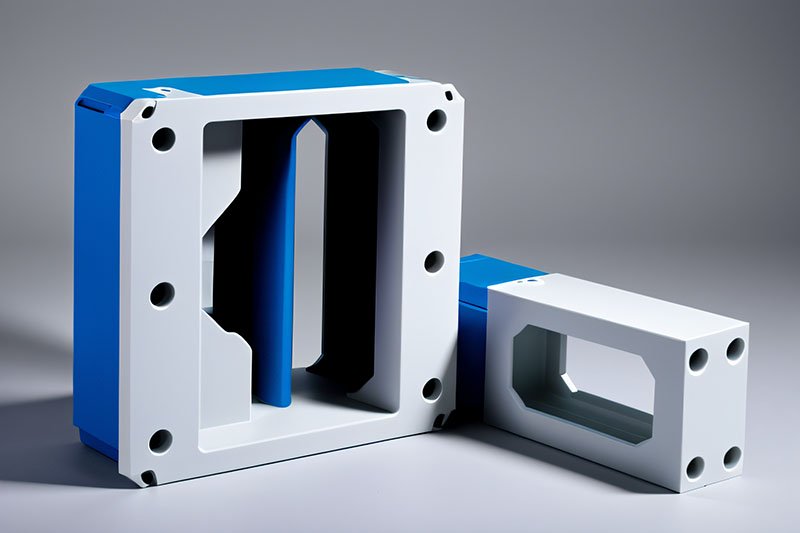

Moulds used in injection moulding consist of two halves: one stationary and one movable. The stationary half is fastened directly to the stationary platen and is in direct contact with the nozzle of the injection unit during operation. The movable half of the mould is secured to the movable platen and usually contains the ejector mechanism. The use of a balanced runner system carries the plastic from the sprue to each individual cavity.

An injection mould can be a simpler two plate mould with a runner system to allow the rubber compound to be injected into each cavity from theparting line or a more complex mould with a number of plates, an ejector system and additional heating elements within the core.

There are two types of casting, open casting and pressure casting. With open casting, the liquid mixture is poured into the open cavity in the mould and allowed to cure. With pressure casting, the liquid mixture is poured into the open cavity, the cap is put in place and the cavity is pressurized. Pressure casting is used for more complex parts and whenmoulding foam materials.

In principle, pressure casting is identical to injection moulding with a different class of materials. Cast moulding can, in fact, produce parts that have identical geometries to injection-moulded ones. In many cases, injection moulding has been a substitute for casting moulding due to decreased parts cost. However, for structural parts, particularly those parts with thick-walls, cast moulding can often be the better selection.

Because the materials flow as low-pressure liquids, tooling is generally less expensive. Low tooling costs make casting ideal for small production quantities and prototypes. It is short to medium-production runs. Liquid cast urethane compounds have outstanding resistance to abrasion, impact, and flex fatigue. Also, complex shapes and thick cross-sections can be produced in many compounds. But this process has longer cycle and cure times than other moulding processes does. And once the material has been moulded, it can not be regrind and reused.

The construction of the mould for cast moulding is almost identical to that of moulds for injection moulding. It consists of two major sections- the ejector half and the cover half which meet at the parting line. The cavities and cores are usually machined into inserts that are fitted into each of these halves. The cover mould half is secured to stationary platen, while the ejector mould half is fastened to the movable platen. The cavity and machining core must be designed so that the mould halves can be pulled away from the solidified casting. Ejector pins are required to remove the part from the mould when it opens. Lubricants must also be sprayed into the cavities to prevent sticking.

Moulds are usually made of tool steel, mould steel ormaraging steel. Since the mould materials have no natural porosity and the molten metal rapidly flows into the mould during injection, venting holes and passageways must be built into the moulds at the parting line to evacuate the air and gases in the cavity.

Although extrusion moulds are quite simple the extrusion moulding process requires great care in the setting up and manufacture and final processing to ensure consistency of product. Pressure is forced through the die plate that has the correct profile cut into it. Variations in feed rate, temperature and pressure need to be controlled.

Unlike compression or injection moulding the rubber is not cured when it comes out of the mould. The raw rubber is laid out on circular or long trays (depending on the profile) and loaded into an autoclave for curing under heat and pressure.

For long continuous lengths a salt bath curing system may be used and for silicone extrusion a continuous heating line is used. The curing process used is dependent upon the quantity and profile of the extrusion required.

Most extrusion moulds are simply one round piece of steel with the profile of the intended extrusion wire cut into them. Allowances are made for the shrinkage, expansion of the intended compound. Extrusion dies are the least complex of the moulds.

These moulds are relatively cheap to build but because of the processing involved minimum run quantities will vary.

Yoddon is a China tooling & injection molding manufacturer. We provide Plastic Injection Molding, Urethane Casting, die casting services, etc. Contact us to get started with a free project review and quote to learn more about our services